September 24, 2025

at September 24, 2025

Categories

Sanitation is one of the most critical factors in industries where cleanliness and compliance directly impact product quality. Every piece of equipment used in processing or […]

September 18, 2025

at September 18, 2025

Categories

Sustainability has become a defining factor in modern industrial design, where efficiency must meet environmental responsibility. Every decision in system design, from material choices to energy […]

September 8, 2025

at September 8, 2025

Categories

Beverage bottling plants demand precision, speed, and consistency at every stage of production. A single delay in the process can disrupt schedules, increase downtime, and affect […]

August 20, 2025

at August 20, 2025

Categories

Modern packaging operations require equipment that strikes a balance between speed, accuracy, and adaptability across a diverse range of product types. Manufacturers that invest in custom-built […]

August 14, 2025

at August 14, 2025

Categories

Modern manufacturing, packaging, and processing lines depend on specialized conveying equipment to move products safely and consistently. Leading conveyor suppliers in Ontario design equipment that addresses […]

August 5, 2025

at August 5, 2025

Categories

Pharmaceutical facilities require the precise movement of products in controlled environments. Cleanroom layouts, strict hygiene standards, and diverse packaging requirements create a need for flexible and […]

July 27, 2025

at July 27, 2025

Categories

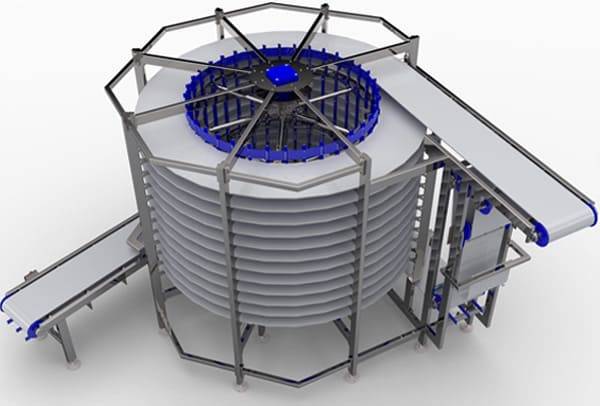

In food production and cold chain logistics, freezing methods vary depending on layout, product type, and operational volume. While both spiral freezers and tunnel freezers serve […]

July 21, 2025

at July 21, 2025

Categories

Fragile product handling presents unique demands in automated packaging lines. Items such as frozen meals, blister-packed pharmaceuticals, and lightweight boxed goods can break, crack, or shift […]

July 15, 2025

at July 15, 2025

Categories

Food manufacturing operations demand equipment that performs consistently across different environments and production requirements. Among the most scrutinized decisions for choosing a food conveyor manufacturer is […]