Spiral Freezer vs. Tunnel Freezer: What’s the Difference?

July 27, 2025

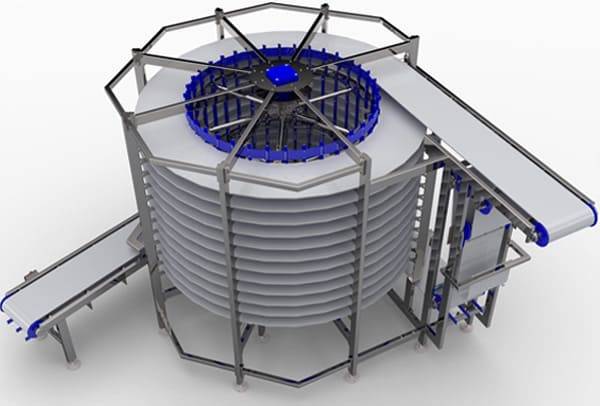

Common Conveyor Configurations Offered by Conveyor Suppliers

August 14, 2025Pharmaceutical facilities require the precise movement of products in controlled environments. Cleanroom layouts, strict hygiene standards, and diverse packaging requirements create a need for flexible and compact conveying systems.

Many spiral freezer manufacturers now supply equipment designed to operate under these specialized conditions. Spiral conveyors bring additional benefits that align with the evolving needs of the industry.

1. Compact Product Handling in Vertical Space

Space is a valuable resource in pharmaceutical plants, where floor areas must be reserved for production lines, inspection stations, and packaging zones. Spiral conveyor manufacturers design equipment that maximizes vertical movement while reducing the footprint on the production floor.

By moving products upward or downward in a continuous flow, spiral conveyors allow engineers to connect multiple levels without interrupting processing. This design supports both batch and continuous production layouts, which is particularly valuable in pharmaceutical operations where every square meter is monitored and regulated.

2. Handling Delicate Packaged Items

Pharmaceutical packaging encompasses a range of products, including blister packs, vials, syringes, and cartons. These products are lightweight, fragile, and sensitive to vibration. Spiral coolers and conveyors reduce abrupt movements by providing gradual inclines and declines.

The smooth belt path helps protect packaging integrity during transfer between sterilization, filling, and inspection stages. Preventing product damage is not only about safeguarding packaging aesthetics but also about maintaining compliance with regulatory standards, as compromised packaging can affect sterility.

3. Cleanroom Compliance and Sanitary Design

Hygiene is central in pharmaceutical manufacturing, and every piece of equipment must maintain strict cleanliness. Spiral conveyors designed for pharmaceutical environments incorporate stainless steel construction, clean welds, and easy-to-access surfaces. This construction enables faster daily cleaning and validation without interrupting production schedules.

Spiral freezer manufacturers who adapt their designs for cleanrooms incorporate materials that resist corrosion and withstand repeated sanitation cycles. In addition, spiral conveyors minimize dust accumulation by keeping moving parts away from the direct product path, which aligns with cleanroom requirements.

4. Flexibility Across Product Types

Pharmaceutical production lines rarely handle a single format. Tablets, liquids, inhalers, and biologics all pass through different packaging workflows. Spiral conveyor manufacturers offer designs that accommodate various product carriers, packaging sizes, and container weights.

Whether moving temperature-sensitive vials from a freeze-drying chamber or transporting boxed products to case packing areas, spiral conveyors can be configured with varying belt widths and load capacities. This adaptability supports long-term use even when product portfolios change.

5. Integration with Inspection and Automation Equipment

Modern pharmaceutical production relies heavily on inspection and monitoring. Spiral conveyors integrate smoothly with metal detectors, vision inspection systems, and weight verification stations. By linking elevation changes with inspection points, production teams reduce the number of transfers between conveyors.

Fewer transfers translate into reduced contamination risk and less mechanical wear on packaging. For cold-chain operations, spiral coolers can be paired with temperature-monitoring equipment to maintain product quality during transitions from refrigerated storage to ambient conditions.

6. Energy and Temperature Considerations

Temperature control is crucial in the pharmaceutical industry, especially in the production of vaccines and biologics. Spiral freezers and coolers allow products to remain within controlled environments for extended periods. This setup prevents temperature fluctuations that may occur during manual handling or with conventional conveyor layouts.

Many spiral freezer manufacturers now build conveyors compatible with insulated enclosures, making integration straightforward in cold-chain facilities. At the same time, spiral conveyors can operate at ambient temperatures, providing a consistent solution across multiple stages of production.

Key Applications of Spiral Conveyors in Pharmaceuticals

Spiral conveyors have become common in pharmaceutical plants for their ability to address critical challenges.

Typical applications include:

- Transporting blister packs between primary packaging and cartoning areas.

- Elevating sterile containers from filling lines to secondary packaging levels.

- Integrating cold-chain handling through spiral cooler units for temperature-sensitive drugs.

- Connecting multi-level inspection processes with minimal transfer points.

These applications demonstrate the practical versatility of spiral systems, illustrating how they enable production facilities to remain compliant while maintaining a smooth product flow.

Evaluate Spiral Conveyor Solutions with Conovey

Pharmaceutical manufacturing requires conveyors that can handle fragile products, meet cleanroom standards, and accommodate multiple packaging types. Spiral designs deliver compact layouts, integration with inspection equipment, and long-term flexibility.

Conovey designs and engineers conveyors that align with these exact needs, providing pharmaceutical facilities with systems that meet strict standards. To learn how a spiral conveyor can improve product handling in pharmaceutical environments, contact Conovey today.